Supermarket “Uoroku” operates 45 stores centered in Niigata Prefecture.

Known for their commitment to quality and locally-focused product selection, they are beloved by many loyal customers.

They own a process center covering meat, prepared foods, seafood, and produce,

with advanced processing capabilities.

In this interview, we spoke with Manager Abe of the Manufacturing Division, who oversees the meat department operations, about the process center’s operations,

the background of Zeus implementation, and its strategic positioning.

- 1. Company Overview [Average Daily Production of 43,000 Packs]

- 2. Background of Zeus Implementation [Equipment Combining Weight Accuracy and Versatility]

- 3. Implementation Results and Challenges [Reduced Effort in Arrangement Work and Weight Checking!]

- 4. Uoroku’s Commitment [Over 3,000 Tonkatsu Daily!]

- 5. Editor’s Note

1. Company Overview [Average Daily Production of 43,000 Packs]

First, could you tell us about this center?

Mr. Abe

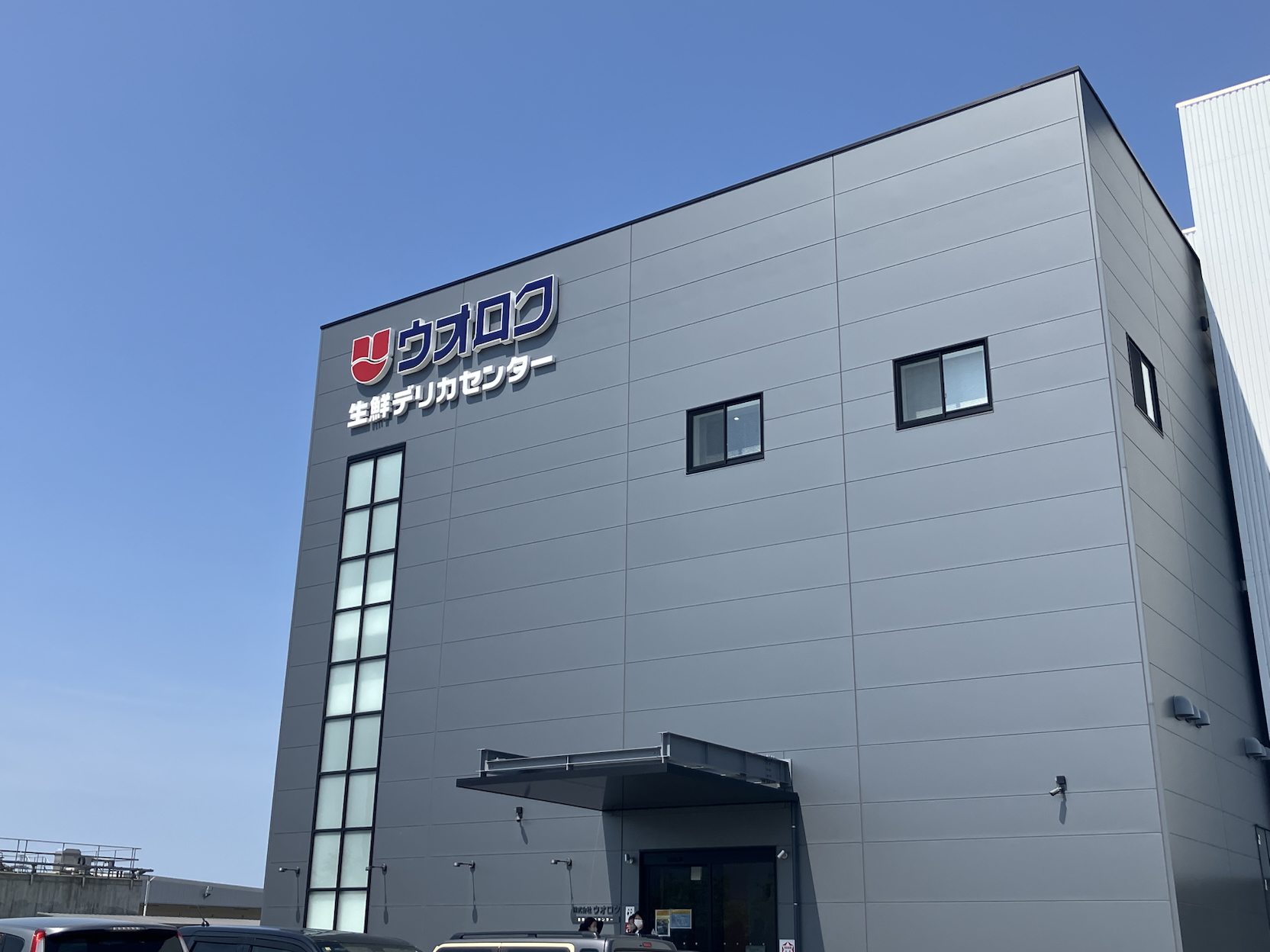

Yes, this is Uoroku Co., Ltd.’s Fresh Delica Center.

Operations began in July 2022, and we’ve just completed our third year.

Our operations cover a wide range: meat, prepared foods, seafood, and produce.

For meat processing, we have an average daily production of 43,000 packs, reaching approximately 70,000 packs during peak periods.

(Photo) Uoroku Co., Ltd. Fresh Delica Center, Niigata City, Niigata Prefecture

Three years since operations began—was labor shortage the main reason for establishing the process center?

Mr. Abe

Yes, exactly.

Securing personnel who could operate slicers in our stores became increasingly difficult,

so we shifted from in-store processing to center-based processing.

However, our existing center had production capacity limitations—

even at full 24-hour operation, the upper limit was just under 20,000 packs per day.

Therefore, we consolidated with another center to expand production capacity and product variety.

Another objective was yield improvement through optimal ingredient utilization and waste reduction.

When processing at individual stores, we had leftover ingredients that couldn’t be fully utilized, resulting in significant waste.

By centralizing processing at the center, we’ve achieved substantial improvements.

Both initiatives have been steadily delivering results.

2. Background of Zeus Implementation [Equipment Combining Weight Accuracy and Versatility]

Could you tell us about the background that led to considering Zeus?

Mr. Abe

The background was updating our old machine, the “Libra 165C,” and restructuring our machine resources to accommodate increased production volume.

For our center, “stable operation even during peak periods” and

“flexible response to product varieties” were priorities, and we determined that

Zeus was the optimal equipment to achieve both.

Our center not only handles outer packaging but also supplies ingredients to the prepared foods department.

In particular, we process large volumes of fixed-weight sliced tonkatsu (pork cutlet) ingredients. Previously, we used Nantsune’s Libra 165C.

We introduced it when switching from frozen to chilled ingredients, and our signature tonkatsu became a hit product.

While Libra served us extremely well, with increasing processing volumes,

it was time to consider introducing a slicer with even higher processing capacity.

Additionally, our Jupiter II, which handles thinly sliced items, was also at full capacity,

so we were seeking a versatile slicer that could complement both machines.

At that time, we saw a Zeus demonstration at FOOMA,

felt it matched our requirements, and requested an on-site demo.

What points did you emphasize during the demonstration?

Mr. Abe

From the beginning, our intended applications were primarily “tonkatsu fixed-weight cutting” with “thinly sliced items” as secondary.

First priority was fixed-weight accuracy—how the weight precision of single-slice fixed-weight cutting compared to our existing Libra 165C.

The accuracy of thinly sliced pack weight control was also important, and we believed Zeus‘s strength lay precisely there.

Second was versatility. In addition to tonkatsu cutting, how much could it replace the thinly sliced items

currently handled by Jupiter II?

In other words, beyond being just “a machine that cuts tonkatsu,”

“could it become a strategic asset supporting the entire center’s production balance?” That was the key question.

I see. So, what were your impressions after seeing the actual demonstration?

Mr. Abe

I’m not just saying this because it’s an interview, but I was genuinely impressed! (laughs)

Impressed!? Could you be more specific?

Mr. Abe

The dual lane feature, definitely. The ability to simultaneously cut fixed weights from two loins was amazing.

Since Libra sliced one piece at a time, for our company with many single-slice fixed-weight items,

I felt the implementation benefits would be significant.

The weight accuracy was equal to or perhaps even slightly better than Libra 165C.

(*Dual lane two-loin input is only available with Zeus Dual)

So dual lane improved productivity for single-slice tonkatsu fixed-weight cutting, and weight accuracy was not an issue.

What about slicing items other than tonkatsu—the versatility aspect?

Mr. Abe

As we confirmed at the exhibition, I felt the pack weight control performance was truly impressive.

Furthermore, I realized again how greatly proper slice alignment impacts productivity.

With Jupiter II, some items had irregular alignment requiring weight adjustment and manual correction,

but with Zeus, the slices align beautifully according to tray dimensions, allowing direct arrangement into finished products.

I thought this was a major advantage.

(Photo) Pork loin meat, dual input operation

3. Implementation Results and Challenges [Reduced Effort in Arrangement Work and Weight Checking!]

Have there been changes in operations since implementing Zeus?

Mr. Abe

Of course, tonkatsu production speed improved dramatically with dual input,

but I feel the improvement benefits for thinly sliced items are even greater.

Jupiter lacked fixed-weight functionality, and alignment could be irregular, requiring weight adjustment and manual correction.

However, with Zeus, we can simply arrange the slices directly,

and weight checking is sufficient with spot checks every few pieces. It’s highly praised by operators.

(Left photo) Jupiter II shingled discharge

(Right photo) Zeus shingled discharge

After implementation, are there any aspects where you think “it would be better if…”?

Mr. Abe

We’d appreciate even higher processing capacity.

Currently, we process pork belly at maximum speed of 200 slices/minute,

but the arrangement work is so easy that idle time occurs with large packs.

For small packs, the speed is just right, but slightly higher capacity would be even better.

Also, there are challenges with weight accuracy. The tonkatsu ingredients we supply to the prepared foods department

are specified at 120-135g, and since they’re sold at a per-piece price rather than by weight,

accuracy directly impacts profit.

Below 120g cannot be used, and excessive weight squeezes profit margins.

Customers might be happy, though! (laughs)

So, further improvements in weight precision would be greatly appreciated.

4. Uoroku’s Commitment [Over 3,000 Tonkatsu Daily!]

Finally, could you tell us about Uoroku’s commitments?

Mr. Abe

Not just because this is a Zeus interview, but

we’re particularly committed to our tonkatsu!

Niigata residents are familiar with your

“This is Uoroku Quality!” TV commercials.

Could you share the key commitment points?

Mr. Abe

We sell it under the product name “Goku-uma Yawaraka Tonkatsu” (Extremely Delicious Tender Tonkatsu), and our commitments are multifaceted.

First, the ingredients: we use pork loin selected by our buyer’s expert eye,

and among those, only portions with the ideal balance of lean meat and fat become tonkatsu ingredients.

We’re committed to chilled temperature processing.

Previously, we used frozen ingredients, but driven by our desire to provide even more delicious tonkatsu,

we switched to chilled processing.

That’s when we met Libra, which has now evolved into Zeus—

it feels like a fortunate connection! (laughs)

Furthermore, we’re committed to having each store carefully bread each piece individually and serve it freshly fried.

https://www.uoroku.co.jp/service/quality/tonkatsu.html

While part of me wants simpler operations, our buyer won’t compromise! (laughs)

Perhaps because this commitment resonates with customers, it’s become a hit product selling over 70 pieces daily per store.

(Photo) Uoroku’s popular product “Goku-uma Yawaraka Tonkatsu”

Thank you, Uoroku and Manager Abe!

Watching those slices made me hungry.

Tonight’s dinner is decided! (laughs)

5. Editor’s Note

During the interview, what touched my heart most was the cleaning robot working in the changing room.

The robot had a label reading “Cleaning Staff” with a note:

“Sometimes gets lost. If you find me, please take me back home.”

The charging station also had a label marked “Break Room.”

The humor and kindness in viewing machinery as “workplace colleagues” shines through.

This perspective toward “colleagues”—this “human warmth”—may be

Uoroku’s true strength.

It naturally connects to teamwork, product-making philosophy,

and what defines “Uoroku Quality.”

Thank you for the delicious tonkatsu!

The menchi katsu was delicious too!

Uoroku Co., Ltd.

Manufacturing Division, Meat Department Manager, Mr. Abe (right in photo)

Our Company

CS Division, Niigata Store Manager, Kizu (left in photo)