This article introduces the current state and challenges in logistics, the characteristics of food logistics, and our company’s proposals for those seeking to improve efficiency in food logistics processes.

Current State and Challenges in Logistics

Here, we explain the current state and challenges facing the logistics industry as a whole.

Driver Shortage

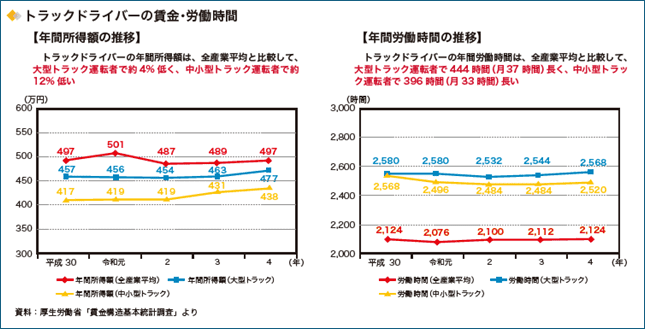

Currently, the logistics industry is suffering from a severe driver shortage. The causes can be attributed to two factors: low wages and long working hours.

As shown in the table below, compared to the all-industry average, annual income is lower and working hours are longer. When converted to hourly wages, the all-industry average is approximately 2,062 yen, while truck drivers earn approximately 1,250 yen, only about 60%.

While the overall working population continues to decline, long working hours and low wages are further accelerating the shortage of truck drivers.

Working Hour Regulations

The overtime work regulations for workers enacted in April 2019, which gave the logistics industry a five-year grace period, ended this April.

Previously, there was no upper limit on overtime hours, but a new limit of 960 hours per year has been established.

Additionally, maximum working hours have been reduced from 16 hours per day to 15 hours.

This creates an extremely difficult situation, especially for the logistics industry, which has significant waiting times and long-distance transportation.

As a result, drivers’ income has decreased due to the inability to work overtime as before, causing drivers to leave the profession, and it has become impossible to secure the previous number of trucks and delivery routes.

Increasing Logistics Volume

Delivery demand accompanying the growth of e-commerce, or online shopping, is expanding year by year, increasing the burden on truck transportation.

The e-commerce market size grew from approximately 9.3 trillion yen in 2018 to approximately 14 trillion yen in 2022, an increase of over 50% in five years, including a significant 21.7% growth from 2019 to 2020 against the backdrop of the COVID-19 pandemic.

Additionally, the number of parcel deliveries increased by 16.5% over the five years from 2017 to 2021, and the growing demand for small-lot deliveries is also a factor putting pressure on logistics resources.

Due to these factors, there is already a labor shortage, and the situation is becoming more severe due to the aging of drivers. While workers under 40 years old account for only 23.9% of drivers by age group, those over 50 represent 48.8%, showing an aging workforce, and the labor shortage will become increasingly serious year by year. If no measures are taken, the transportation capacity shortage is predicted to reach 14% in fiscal 2024 and 34% in fiscal 2030. Imagine trucks for receiving and shipping being reduced to two-thirds.

This means that if we continue current practices, one-third of products will not be delivered.

Characteristics and Challenges of Food Logistics

Here, we explain the characteristics and challenges specific to food logistics within the broader logistics field.

Temperature Management

Since food is temperature-sensitive, appropriate temperature management is required at each stage: frozen, refrigerated, and ambient.

Especially for fresh food, strict control is required as quality deteriorates easily if temperature management is neglected.

Expiration Management

Because expiration dates and best-before dates are set, rapid distribution is required.

This makes accuracy in inventory management and delivery schedules critically important.

Hygiene Management

Hygiene management is strictly regulated to ensure food safety.

This includes cleanliness of distribution centers and delivery vehicles, and thorough handling methods.

Multi-Product Small-Lot Delivery

Small-lot deliveries are frequently made in response to consumer needs.

Especially with the expansion of online food sales, rapid delivery services are required.

Seasonal Fluctuations

Because demand fluctuates with seasons, flexible responses are necessary.

Especially during peak seasons, adjustments to inventory management and delivery planning become important.

As described, food logistics has unique characteristics that tend to worsen working conditions, making it even more difficult to attract workers. Additionally, the three fresh food categories—produce, seafood, and livestock products—are largely delivered from production areas to consumption areas through long-distance transportation. If what previously took 2 days now takes 3 days, it will naturally affect quality and freshness, requiring more efficient logistics processes. It’s necessary to organize and address issues that can be resolved in the short term and those requiring medium- to long-term approaches, first determining where to begin.

Proposals from Nantsune

Automation of Cardboard Box Unpacking Process

“ABOT,” which our company handles, is a machine that automatically unpacks cardboard boxes by cutting 3 or 4 sides of the top surface. Main features are as follows:

・Processing capacity of up to 450 boxes/hour

・No need to register box sizes, random size input possible

・Cutting depth adjustable in 0.1mm increments

Additionally, at the recent FOOMA JAPAN 2024, we exhibited “SCOT” (under development) as a reference.

SCOT maintains the same processing capacity while achieving simple mechanisms with domestic manufacturing, miniaturization, and cost reduction, and we are developing it with the goal of starting orders in January 2025. We will continue to release new information, so please look forward to it.

At Nantsune, we can handle all cases, including cutting tape portions that ABOT and SCOT cannot handle, as well as various box shapes, sizes, and processing capacities. Please feel free to consult with us.

Automation of the Entire Receiving Process, Including Pre- and Post-Unpacking Steps

Automating only unpacking has limited effects on overall efficiency improvement.

By introducing automation processes throughout the entire receiving process, effects and efficiency can be dramatically improved.

For pre-processes: depalletizing to automatic feeding.

For post-processes: lid removal, content extraction, connection to subsequent processes, and automatic disposal of empty boxes—we can propose automation of the entire receiving process.

Conversion of Packaging Methods

By converting to packaging methods such as MAP packaging and skin pack packaging that can extend expiration dates and improve loading efficiency, logistics efficiency can be improved and optimized.

MAP packaging is a technology that can extend expiration dates by using barrier packaging materials and injecting gas suitable for the type of food.

Effects vary depending on the food, but for meat products, approximately one week of expiration extension can be expected compared to stretch film packaging. In Europe, MAP packaging has become standardized for meat, ham, sausages, etc., to reduce food waste.

Meanwhile, skin pack packaging is a method where products are placed on trays, heated film is applied from above, and the film is adhered tightly to both the product and tray, allowing for approximately 10-20 days of expiration extension compared to stretch film packaging.

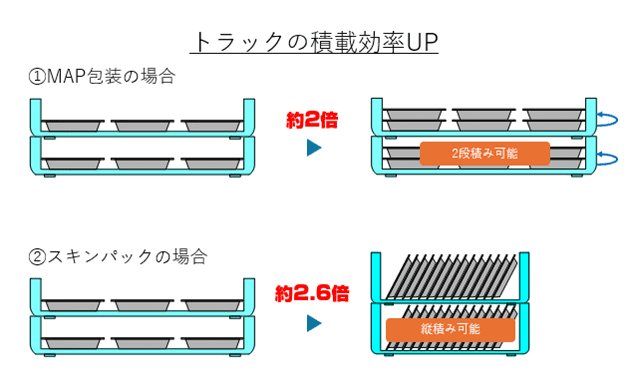

These packaging methods also have the characteristic of higher strength than current stretch film packaging, allowing for stacking and angled placement, thus improving loading efficiency.

By converting to packaging methods that can extend expiration dates and improve loading efficiency, it becomes possible to reduce the number of truck trips themselves and respond to logistics capacity shortages.

Nantsune has also begun handling packaging machines manufactured by Spain’s ULMA that can perform these packaging methods.

Customers considering conversion of packaging methods should please consult with our company.