NTD-165F

Libra 165F

Libra 165F

Product description

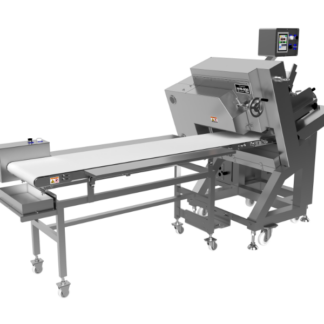

3D Fixed-Weight Slicer NTD-165F Libra 165F

High-speed fixed-weight system that enables high-volume processing with minimal staff!

Features of Libra 165F (NTD-165F)

High-Speed Fixed-Weight Slicing

- 3D measuring device reads the shape of raw material before slicing.

- No need for weight feedback, enabling high-speed fixed-weight processing.

- Freely arranges fixed-weight items on conveyor with customizable continuous or intermittent slice count and intervals.

- ※End loss discharge: Discharging the final irregular portion without slicing. Discharged portions can be used for other product materials.

Non-Contact Measurement Improves Product Value

- Shape reading performed non-contact using displacement sensors for hygiene.

- Does not deform products during measurement.

- No stress on products, preserving product value.

Chucking System for Securely Holding Frozen Ingredients

- Claws automatically hold ingredients securely to prevent thickness variations.

- After slicing is complete, claws release from ingredients.

- Remaining ingredients are discharged onto the conveyor.

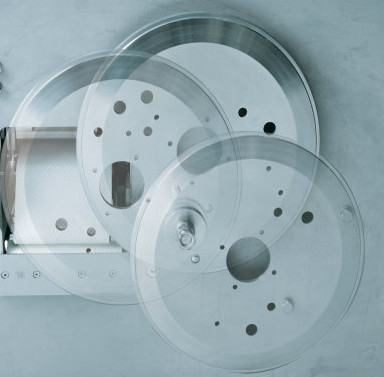

Circular Blade with Stable Cutting Performance

- Our proprietary circular blade eccentric technology achieves exceptional cutting performance.

- Semi-automatic sharpening with dedicated grinding device maintains stable cutting performance.

- Changeable blade position allows 3 times longer use compared to standard circular blades.

- Uses specialized frozen food blades.

Easy-to-Use LCD Touch Panel

- Features easy-to-see and easy-to-operate color touch panel.

- No complicated settings required.

- Anyone can easily perform fixed-weight slicing.

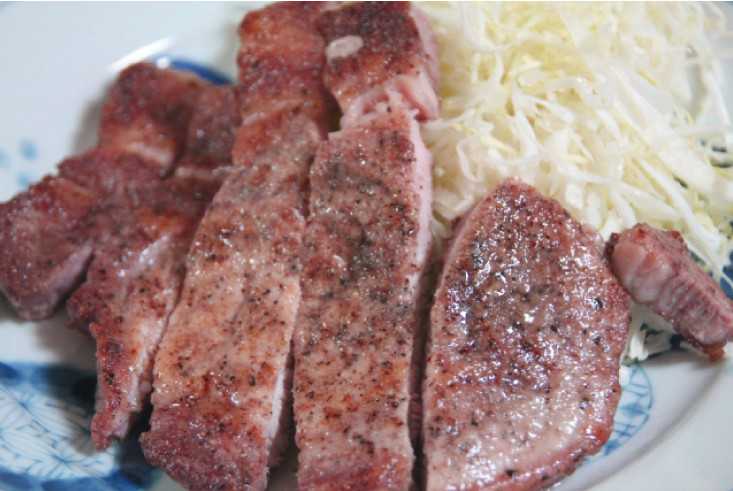

Maximum 250 Slices/Min for Regular Slicing

- Also capable of fixed-thickness cutting.

- Can slice wide range of ingredients from pork loin ginger stir-fry to yakiniku materials.

Product Documentation

Main Unit Specifications

| Machine Dimensions | Width 911 × Depth 1,326 × Height 1,567mm |

|---|---|

| Machine Weight | 306kg |

| Power Supply | 3-phase 200V 50/60Hz 20A |

| Motor Capacity | For blade: 0.4kW × 1 unit For feeding: 0.4kW × 2 units |

| Slicing Capacity | Fixed-weight slicing: MAX 5,000 slices/hour ※Based on raw material length 500mm, thickness approx. 12mm. Fixed-thickness slicing: MAX 15,000 slices/hour |

| Slice Thickness | (0)-50mm |

| Sliceable Dimensions | Width 165 × Height 100 × Length 600mm |

| Suitable Slicing Temperature | -5℃ to -2℃ ※Varies slightly depending on meat thickness, quality, and shape. |

3D Measuring Device Specifications

| 3D Measuring Device Dimensions | Width 779 (Belt width 390) × Depth 1,542 × Height 1,397mm |

|---|---|

| 3D Measuring Device Weight | 205kg |

| 3D Measuring Device Motor Capacity | For sensor linear motion: 0.3kW × 2 units For 3D measuring device conveyor: 0.9kW × 2 units |

| 3D Measuring Device Conveyor Speed | 0-13m/min |

Conveyor Specifications

| Conveyor Dimensions | Width 373 (Belt width 220) × Depth 1,209 × Height 1,002mm |

|---|---|

| Conveyor Weight | Approx. 51kg |

| Motor Capacity | For conveyor: 0.9kW × 1 unit |

| Conveyor Speed | 0-22m/min |

※Specifications may be changed without notice for product improvement.